The vacuum circuit breaker (VCB) is at the core of many modern switchgear systems, including solid-insulated and gas-insulated designs. Its purpose is simple but vital: to interrupt current flow safely under normal and fault conditions. The interruption process relies on separating conductive contacts and extinguishing the arc that forms between them.

When breaker contacts open, an arc forms as current continues to flow through ionised particles. In air- or gas-insulated systems, this arc ionises the medium and can persist until the next current zero crossing. However, in a vacuum, there are no gas molecules to sustain ionisation. The arc exists briefly as a plasma of vaporised contact material and is rapidly extinguished when the current passes through zero. This makes vacuum interrupters exceptionally fast and reliable in interrupting fault currents.

A vacuum interrupter contains two separable contacts within a hermetically sealed ceramic envelope. Metal end plates are brazed to each end to maintain vacuum integrity and support the internal structure. One contact remains fixed while the other moves through a flexible metal bellows that preserves the vacuum seal. Internal shields protect components from metal vapour produced during arcing.

This simple yet robust construction gives VCBs a long service life, minimal maintenance requirements and excellent dielectric recovery characteristics – key advantages for medium-voltage applications from 3,3 kV to 33 kV.

Contact design and arc control

Contact geometry plays a decisive role in controlling the arc and minimising erosion. The basic butt-type contact (a flat opposing surface) is adequate for current ratings up to about 10 kA. At higher fault currents, however, the arc tends to concentrate in a single spot, leading to excessive local heating and wear.

To manage higher breaking capacities, two advanced contact designs are used: radial magnetic field (RMF) and axial magnetic field (AMF) types.

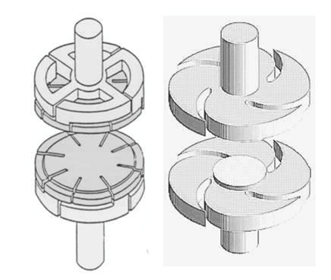

- RMF contacts have spiral or slotted geometries that generate a horizontal magnetic field perpendicular to the arc current. This induces a tangential force that rotates the arc around the contact surface, dispersing heat and preventing erosion at a single point.

- AMF contacts feature identical helical grooves on both contacts, creating a magnetic field aligned with the contact axis. Here, the arc current and magnetic field are parallel, producing a spinning motion that evenly distributes the arc across the contact face.

Axial (a) and Radial (b) magnetic field contacts. Source: ABB

Performance and application

AMF contacts offer superior arc diffusion and are preferred in breakers designed for higher fault levels. Their ability to maintain uniform erosion extends operating life and stability. Vacuum interrupter circuit breakers are now standard across utility, industrial and renewable installations, offering compact design, environmental safety and reliable performance without the use of SF₆ gas.