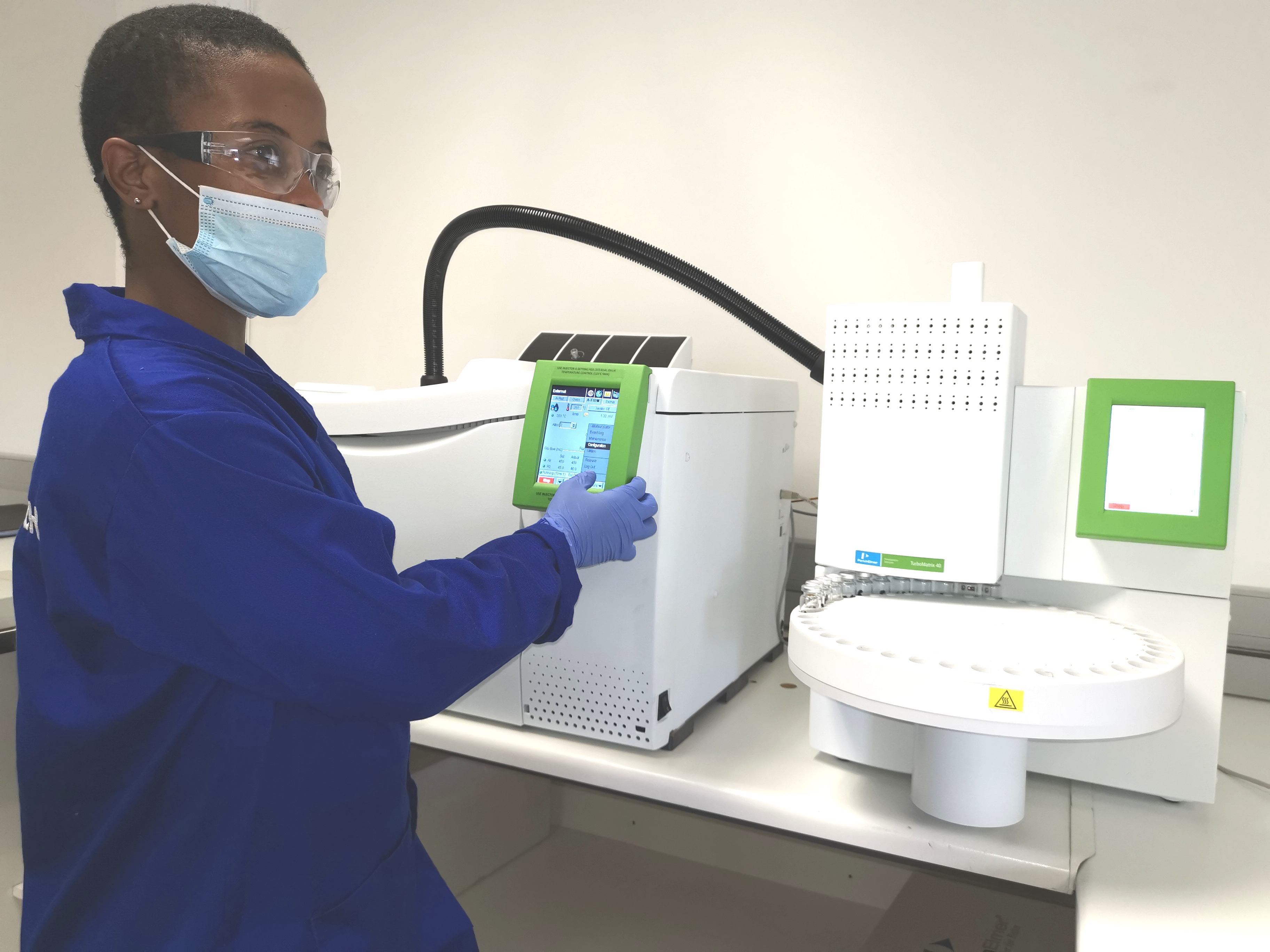

Well known reliability solutions specialist Oilwatch have established another transformer insulating fluid laboratory in Durban to expand on its existing Gauteng-based transformer asset reliability service.

Transformers are critical apparatus for providing reliable energy. No one can precisely predict when equipment will fail, but it is essential to manage risk. Compared with the cost of premature failure, regularly scheduled oil testing is a cost effective and sound management practice that can be used to extend the life of transformers.

Dissolved gas-in-oil analysis (DGA) is the most powerful and cost-effective tool in improving transformer reliability.

DGA detects a wide range of problems in the early stages and then throughout the life cycle. It is a great asset management tool for expensive apparatus such as transformers and has also been applied to load (energised) tap changers, oil circuit breakers and other oil-filled devices. It has been applied to a variety of dielectric liquids beyond mineral oils, including natural and synthetic esters, silicone and high temperature hydrocarbons.

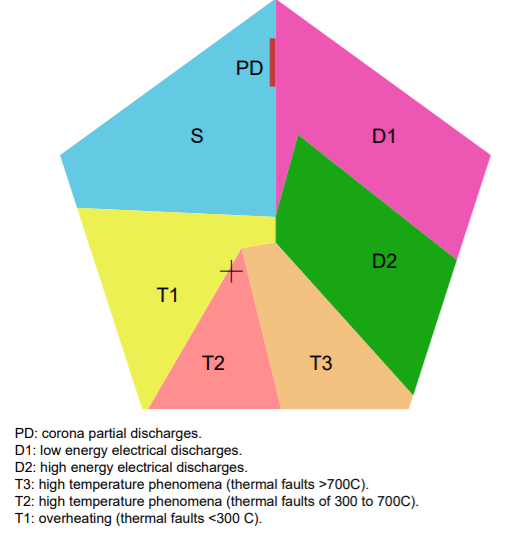

It has now been firmly established that Duval triangles and Duval pentagons fault interpretation for dissolved gasses (DGA) is one of the best diagnostic methods to determine the fault condition within power transformers.

This technique for mineral oil is now a part of IEC 60599 – 2015 and IEEE c57.104-2019 standards. Using fault categories of Duval triangles and Duval pentagons, the six basic types of faults (PD, D1, D2, T3, T2 T1) are detectable.

“These diagnostic tools have been incorporated into the Oilwatch cloud based data management software which guarantees consistency and accurate diagnostic reporting”, says Ian Gray, an internationally recognised industry expert.

Oilwatch transformer division director Shiven Brijlal says, “I am always faced with the challenge of meeting and managing clients’ expectations. In my experience, the core client expectations fall into three main categories: quality, speed and cost and we are committed to manage these in order be a world class service provider.

We are proud of the Oilwatch team’s achievement in attaining the coveted ISO/SANAS 17025 general requirements for the competence of testing and calibration laboratories, which has been a culmination of teamwork and commitment to this quality standard.

Beyond a quality management system, accreditation is a global standard which recognises the technical competence of a laboratory to perform specified tests.

This assures our clients that we meet their expectations and conform to specific requirements. Reliable test data is paramount to our organisation to provide recommendations on remedial actions based on relevant standards and expert knowledge”.

Contact Oilwatch, Tel 087 238-2188, support@oilwatch.co.za, www.oilwatch.co.za