by Daniel Jansen, Eaton

Commercial and industrial buildings depend on safe and reliable electrical systems to ensure continuous operation. Failure in electrical systems disrupt operations, results in lost revenues, and creates safety hazards. Efficient energy management, avoidance of costly repairs through predictive maintenance and adoption of connectivity and automation, where appropriate and economically viable, are all considered to be good practice from both financial and sustainability perspectives.

Circuit breakers are one of the core components of switching systems and play an important role as safety devices for low-voltage grids. They protect systems and equipment, but also make an important contribution in reducing the impacts a short circuit or arc flash could have on operating personnel. The selection of the right circuit breaker contributes to the reliability of the system as a whole and influences the availability and safety of equipment and systems.

The role of circuit breakers

Electrical power is the lifeblood of every commercial and industrial building. However, the safe and reliable delivery of electrical power cannot be taken for granted. Circuit breakers are an established mechanism for effectively safeguarding power distribution and protecting large loads. Even in their simplest form, as electromagnetic switches without any additional electronics, these breakers protect electrical equipment against thermal overloading and short circuits in the event of a defect.

The latest circuit breakers incorporate electronic tripping systems that perform with greater precision in the event of overload or short circuit. The more advanced models even offer digital capabilities that intelligently monitor the condition of the circuit breaker and provide advance warning where predictive maintenance may be required.

Understanding the risk

Circuit breakers address two main risks: overloads and short circuits. Thermal protection normally reacts to an overload. In LV applications, short circuit current can reach multiples of overload current. This current could cause an arc flash at over 10 000°C – posing a major fire hazard, with the risk of extensive damage to systems and equipment, and can endanger the lives of personnel.

Defending your building from danger

To fully protect people, assets and business continuity from the destabilising effects of short circuits and overloading, as well as reducing the severity of arc flash, it is critical to ensure circuit breakers meet regulatory standards and that best practice is applied to the fitting and maintenance of these devices.

Enhancing safety and reliability

Step 1 - Selecting a circuit breaker: While safety fuses have a lower upfront cost, in the longer term, both direct and indirect costs may rise. When tripped, circuit breakers do not need to be replaced and instead can be quickly and easily switched back on once the fault has been cleared. Since circuit breakers can be activated without risk under all network conditions, they are also suitable as main breakers for equipment or systems. Moreover, the range of functions that circuit breakers offer can be expanded through the use of models with electronic or digital tripping units.

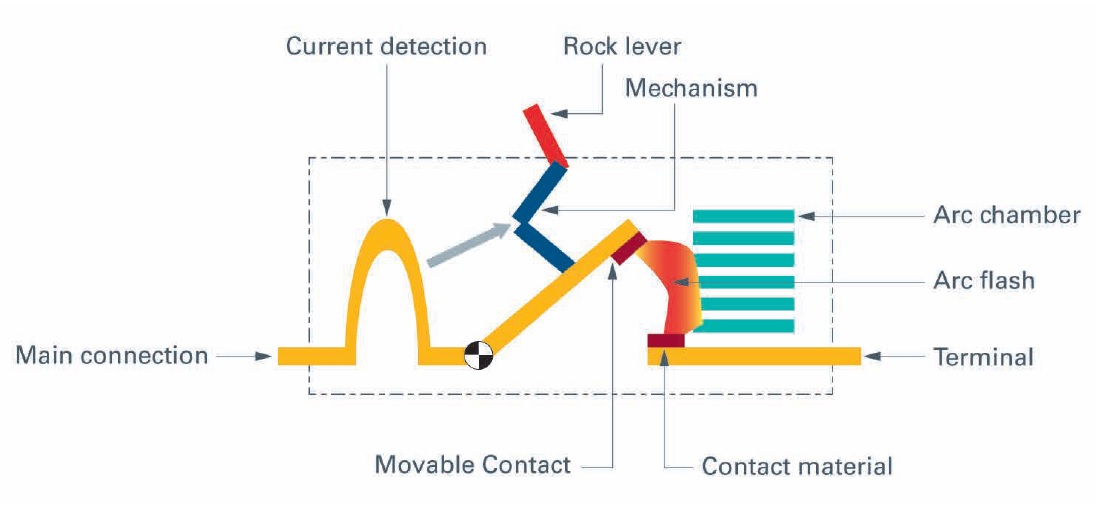

When tripped, the interruption of the electrical supply causes an arc flash between the movable contact and the fixed contact. If there is a significant difference in voltage, the gas between the contacts ionises, resulting in gas being discharged in the form of an electric arc. Circuit breakers have a variety of mechanisms that can quickly extinguish such an arc and thereby interrupt the flow of current. The design of circuit breakers distinguishes, according to the method used to extinguish an arc, between zero-current and current-limiting circuit breakers.

- Zero-current takes advantage of the fact that an arc that uses alternating current will extinguish itself at zero current flow. In the following half-cycle, the gap between the contacts is large enough that the arc will not re-ignite.

- Current-limiting circuit breakers interrupt short-circuit surge current before it reaches its theoretical maximum value. The contacts open within a few thousandths of a second with the aid of a strike armature, which immediately directs the arc into the arc chamber.

Traditional circuit breakers detect an overload or short circuit via thermo-magnetic trip mechanisms. During an overload, a bi-metal strip is warmed up enough so that its bending activates the trip pin in the switch. Short-circuit currents trip the switch by magnetic force. The newest generation of circuit breakers uses electronic tripping systems. These operate with greater precision than thermomagnetic trip units and demonstrate superior performance by reliably switching operating current, overload and high short-circuit current. In addition, the current status of the circuit breaker, and the electrical data of the circuit it is protecting, can be easily transmitted to a control system or to an automation network. Analysis of this data provides for greater efficiency in upkeep through predictive maintenance.

Step 2 - Conforming with standards: Circuit breakers in LV grids (circuits with rated voltages up to 1000 V alternating current or 1500 V direct current) must comply with Sections 1 and 2 of the requirements specified in IEC/EN 60947. This standard applies regardless of the rated current, design or anticipated use of the circuit breaker. The standard defines the characteristic properties of circuit breakers, such as rated operational voltage (Ue), the rated maximum short-circuit breaking capacity (Icu) or the rated current (Ie).

The standard not only sets out requirements for design but also for operational performance during switching and overload or short circuit operation. Only if a circuit breaker satisfies all the requirements specified in the standard, is it considered suitable for protecting against an electrical circuit.

Step 3 - Going beyond the standard to eliminate residual risks: Even conscientious application of the respective product and installation standards does not eliminate all the risks of working with electrical machinery and systems. A residual risk remains. Human error, lack of knowledge and misjudgment are common causes of accidents, alongside proximity to live components and damaged or malfunctioning electrical systems and equipment.

Reducing human error

The most common cause of accidents is failure to observe the five safety rules to ensure a zero-potential environment when conducting work on electrical systems:

- Disconnect

- Ensure that devices cannot be accidentally switched back on

- Ensure that the device is no longer live

- Ground and short-circuit

- Cover or fence off any nearby live components

Protective clothing

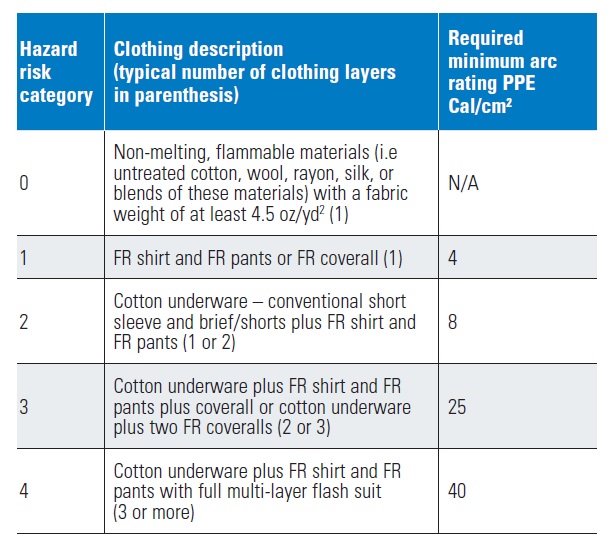

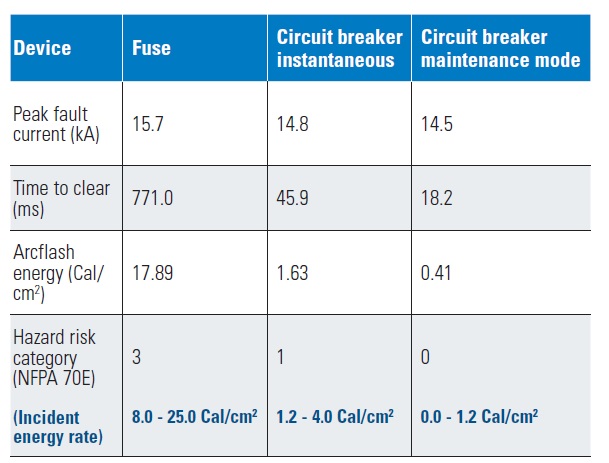

Given that arc flashes can reach temperatures exceeding 10 000°C, appropriate personal protective gear is required. The calculation of arc energy released in the event of a defect serves as the basis in selecting personal protective wear. It is dependent, among other factors, on safety system switch-off time, maximum three-pin short-circuit current and arc output. This means that measures that reduce arc energy also lower the arc protection category for personal protective gear. In certain circumstances this can significantly facilitate maintenance and repair work.

Advanced circuit breakers

State-of-the-art circuit breakers, like the digital NZM from Eaton, offer both the properties stipulated by standards organisations as well as additional features that contribute to safe operation. They are designed not only to protect people and facilities against injury or damage, but also for enhancing the availability of electrical systems, reducing maintenance and diagnosis costs. The electronic tripping units in state-of-the-art circuit breakers not only provide for precise breaking and therefore additional safety, they also can supply data on current status and error messages, as well as diagnosis and metering data. When fitted with a communication interface (such as Modbus, Ethernet or Profibus), they can be integrated into a system’s information flow and thereby contribute to data transparency in commercial and industrial buildings.

Safer servicing

Digital circuit breakers with a maintenance mode are useful for applications in which a system cannot be switched off for servicing. In these situations, servicing has to be performed while the system or nearby components are live. This heightens the risk of an incident in numerous ways. For example, an electrical arc can occur when a maintenance person disconnects a live cable that accidentally slips out of his hand and then comes into contact with the switch box housing, or when a tool falls into part of the system.

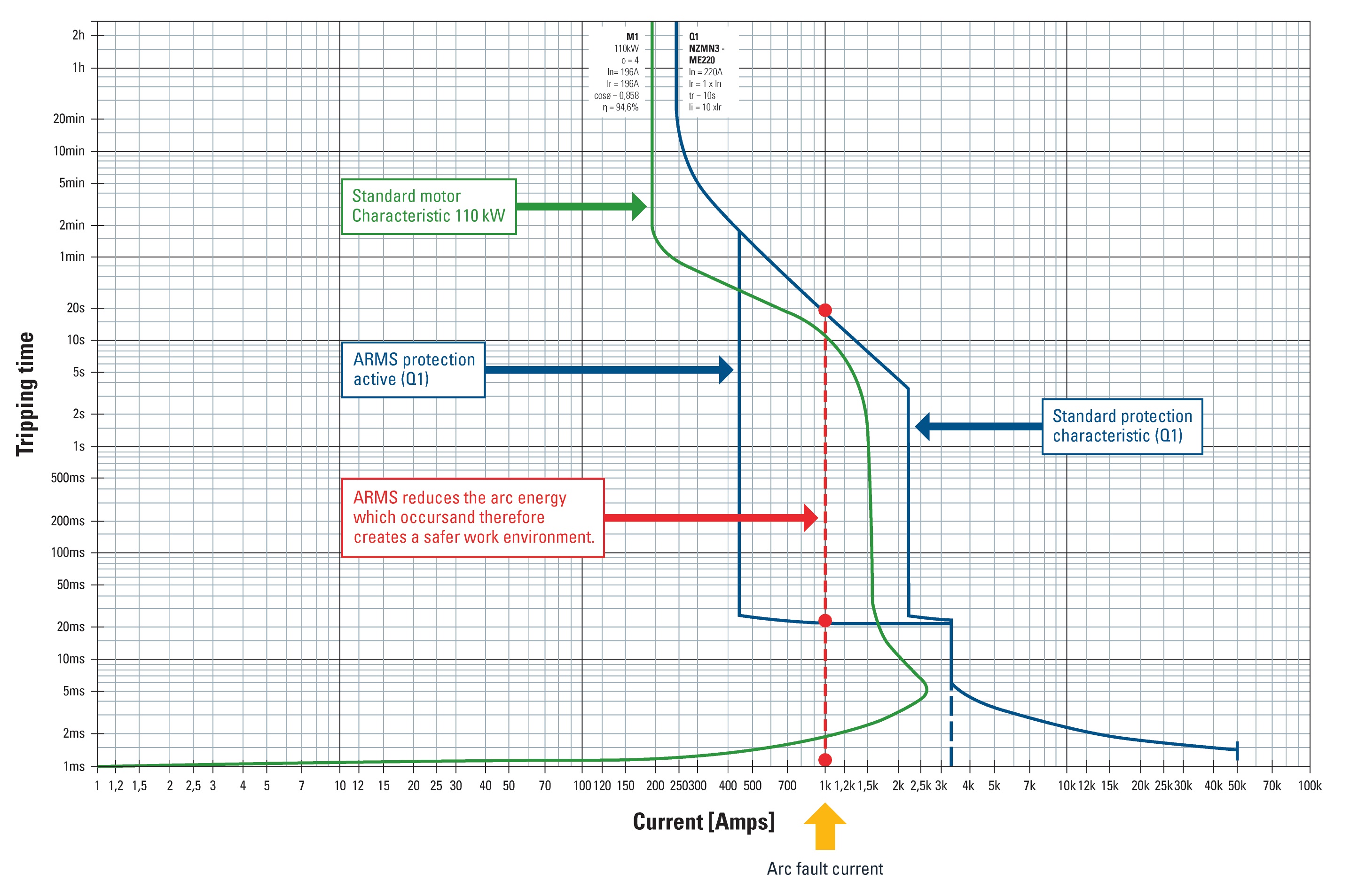

Since the arc has high impedance and low current flow, it is generally perceived as an overload rather than a short circuit due to the relatively low amplitude of the current, compared with a full metal short circuit. If the circuit breaker is set to the normal overload setting, this results in delayed triggering, which endangers the engineer. If the same incident occurs with a circuit breaker in maintenance mode, the breaker extinguishes the electric arc almost instantly using the non-delayed instantaneous tripping function, which usually takes between 10 and 20 ms. The typical lag time caused by overload is overridden as long as the breaker is in this mode. The maintenance mode uses a redundant processor to ensure the highest degree of safety. This reduces total breaking time, which, in the event of a fault, ensures that repair personnel are exposed to the lowest possible arc energy.

In our example, this would result in 1000 A of electricity. The ARMS maintenance mode feature causes the breaker to trigger in 20 ms instead of 20 s.

Integration with door contacts

To reduce the impact of errors like these, the maintenance mode on digital circuit breakers can be coupled with door contacts, for automatic activation as soon as the control box door is opened. This coupling makes it possible to avoid a number of potential risks when servicing a system:

- Even if a technician is unaware of the maintenance mode or how it is activated, the circuit breaker is automatically in servicing mode whenever the control box door is opened.

- Even a trained technician does not need to remember to first activate the maintenance mode before he starts to work on the control box.

- If work is being conducted with the control box doors open, even though the system is not adequately protected against the power being unintentionally switched back on, the servicing mode is automatically activated if the system is switched on. Additionally, maintenance mode can be activated remotely, as well as via the control system.

Additional breakers

There are other risks to personnel working on electrical systems than those posed by electric arcs. Even if a control box is constructed with the aim of making it impossible for it to come into contact with live conductors (such as bare cable ends and clamps), there may be situations in which live conductors are lying about. To reduce the impacts of accidents resulting from coming into contact with live lines, an additional residual current device is required for the respective electrical circuits. Eaton also supplies supplementary protection for circuit breakers.

Zone selectivity

Selectivity within cascading energy distribution ensures that the protective device directly upstream from the fault is activated. This means that the shut-down only applies to the part of the system where the fault occurred, which limits the effects of an overload and minimises interruptions to operations. Time selectivity is generally employed in providing for consistent selectivity. This means that the tripping period of hierarchically arranged circuit breakers is delayed and a shorter delay period assigned to the upstream breakers. The closer the protective device is to the power input, the longer the delays. The disadvantage of this method is that the trip times and energy levels allowed by the safety function are particularly high the closer they are to the power source.

Zone selectivity interlocking (ZSI) offers an alternative. It allows the circuit breakers to communicate with one another via a signal cable. In contrast to time selectivity, this alternative makes it possible to quickly switch off at any point in the low-voltage circuit and thereby reduce to a minimum the energy released, which in turn decreases the thermal and dynamic system load.

Lifespan management

When a short circuit is disconnected directly upstream from the power source or if this is pending for a longer period owing to time selectivity, a significant strain is placed on the circuit breaker, causing contact wear. If the breaker’s contacts are too worn, it ceases to function, and no current flow is possible. In this case, the system or equipment can no longer be used until the breaker has been replaced.

Until now, the system operator had to decide whether to replace the breaker based on an event log or other record of incidents. However, today’s more advanced digital circuit breakers provide precise information on their life spans and make this information available locally as well as via the communication interface. This enables engineers to decide within seconds of a short circuit whether a circuit breaker can remain in use or whether to replace it – which makes a significant contribution to the safe operation of systems.

The lifespan indicator function in the digital circuit breaker calculates the wear and tear of a component involved in a disconnection process. Burnout of contact surfaces is one of the primary parameters calculated by a trip counter, in combination with the amplitude of the current during opening. Beyond that, however, there are various other modules in the breaker that guarantee that the safety features continue to operate in the event a fault occurs.

Newer digital circuit breakers supply test programs that monitor and record the functionality of these modules. It is possible, for example, for the digital NZM to monitor the entire metering and triggering chain. This includes:

- Transformer continuity testing

- Secondary input testing

- Depending on the test, the breaker may be tripped: this tests the functionality of the trip actuator

Regular inspection or additional testing following a short circuit provides for greater reliability of building operations.

Temperature monitoring

To optimise preventative maintenance, it is advisable to supplement communication-capable circuit breakers with temperature monitoring. The main circuits of a switching system often carry several thousand amperes. Overloaded collection or distribution busbars, connections in the primary circuit that have not been properly tightened, clogged vents or other abnormalities can produce ‘hot spot’ zones in the system. These unsafe temperatures create a fire hazard or, in the event of a loose connection, the risk of an arc flash. With a diagnosis system for temperature monitoring, the sensitive parts of a switching system can be monitored round the clock. The systems that Eaton provides consist of autonomous temperature sensors installed on collector busbars and junctions, which transmit data to control devices.

When the system detects high temperatures in a particular area, the communication interface is able to trigger the appropriate circuit breaker before a fire or an arc flash can occur. It can also detect any loose screw connection, enabling it to be tightened as a preventative measure.

Additional arc protection

Eaton has long supplied technical solutions that supplement the operation of circuit breakers and provide added protection including for open switching systems, such as the ARCON Arc Fault Protection System. This unit detects arc flashes through two separate variables:

- Transducers register the overcurrent that generates electric arcs

- Sensors detect the extremely bright light emissions produced by an arc flash

These analog sensor signals are converted into digital signals and transmitted to the central analysis unit, which activates an extinguisher within less than 2 ms. The supplying circuit breaker is tasked with disconnecting the open collection busbar segment from the grid.

Conclusion

State-of-the-art circuit breakers do more than reliably protect equipment and systems within commercial buildings against overloads and short circuits. Digital trip units provide numerous functions that are not currently stipulated by relevant standards. Investing in this type of circuit breaker not only provides additional protection of personnel but also reduces downtime, simplifies maintenance and increases efficiency of the business as a whole. This helps to ensure commercial and industrial buildings operate safely, reliably and cost-effectively.

Send your comments to rogerl@nowmedia.co.za