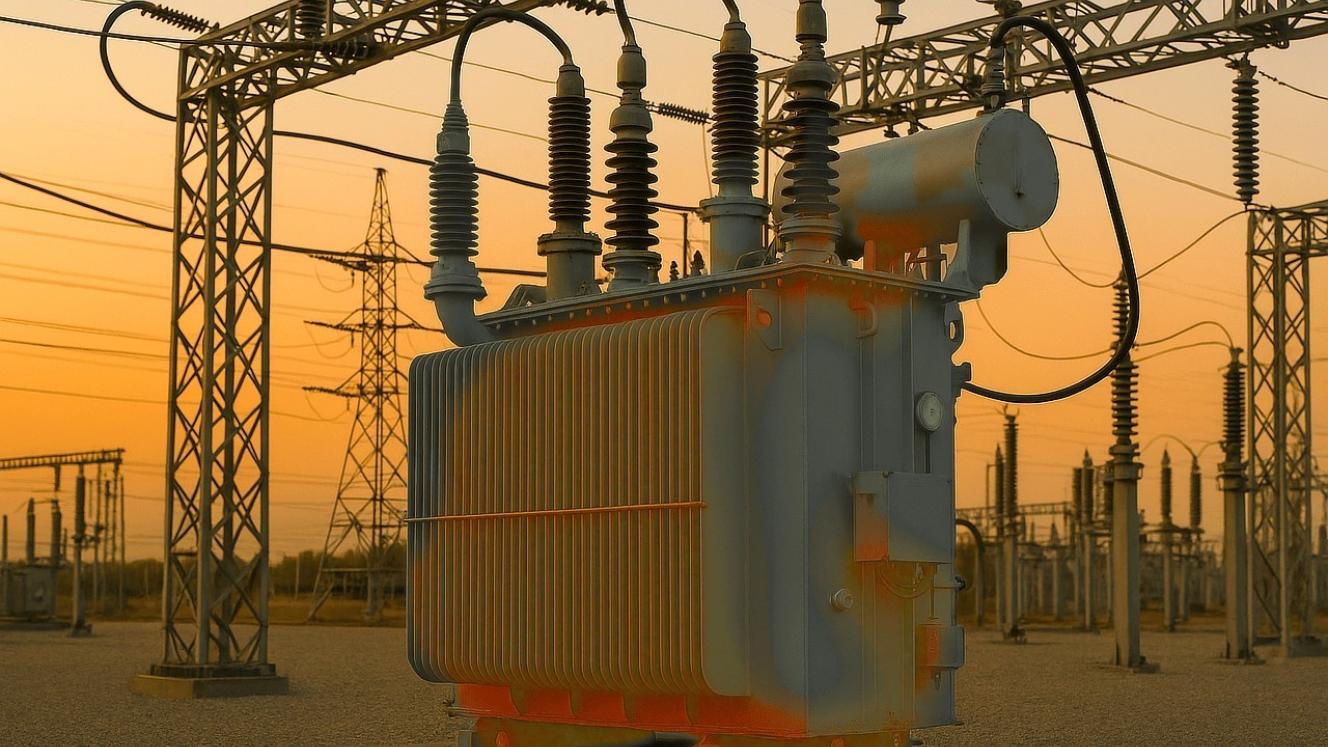

Transformer fleet management is no longer business as usual in Southern Africa’s shifting power landscape.

Old assumptions meet harsh realities

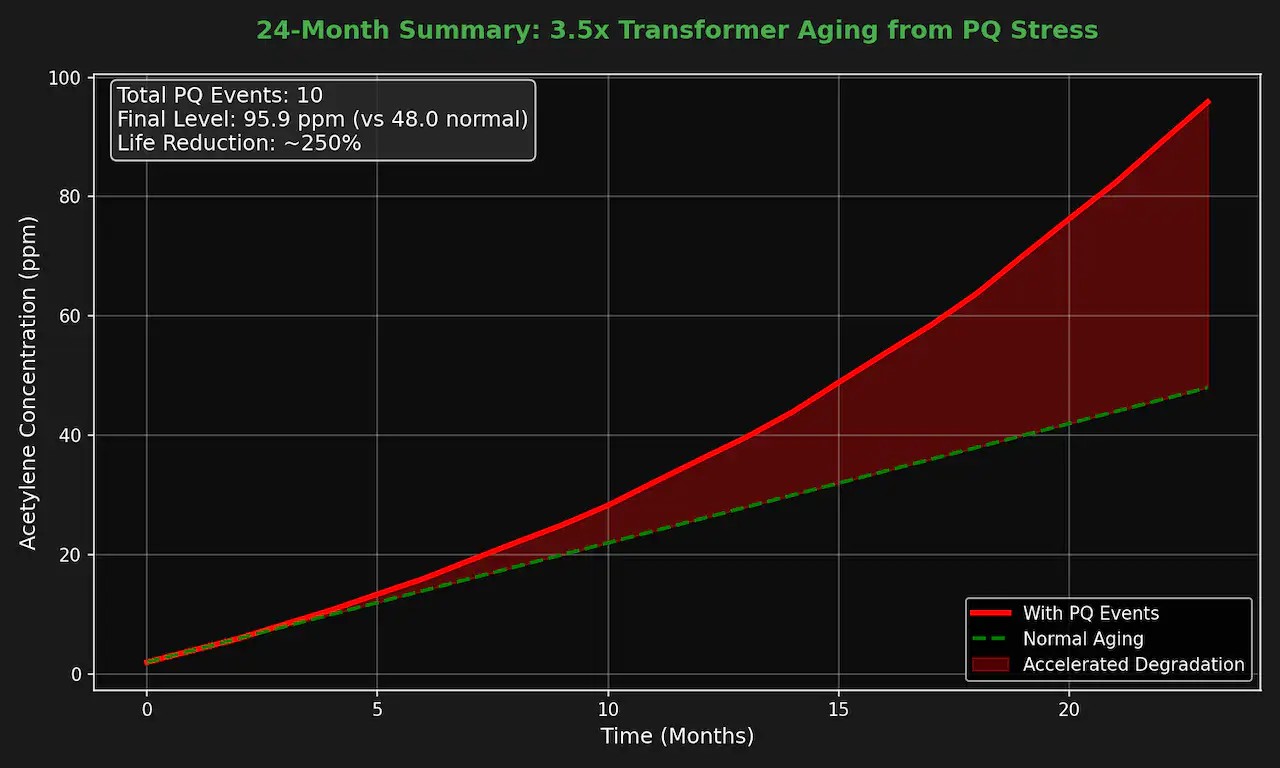

Surging renewables, ongoing load shedding and decentralised generation are exposing vulnerabilities across transformer fleets in the SADC region. Bidirectional power flows from independent power producers (IPPs), fluctuating loads from PV and battery systems, and frequent grid interruptions are contributing to accelerated transformer degradation.

In South Africa alone, dozens of burnt-out transformers are replaced each month. In one municipal water facility, failure of an overloaded medium-voltage transformer left 40 000 residents without water for three days – with no harmonic monitoring or advance warning in place.

From reactive to proactive

Permanent power quality monitoring is no longer a luxury – it’s a survival tool. Industrial operators and IPPs are adopting edge-based devices such as the multifunctional VECTO 3 to detect harmonics, overloads and voltage instability in real time. These systems provide early warning to prevent fires, equipment trips and unplanned shutdowns.

Asset owners are adopting a phased approach to transformer fleet management:

- Install permanent monitoring on critical transformers to establish baseline stress data.

- Identify and rank high-risk units using harmonic profiles, load imbalance and voltage event data.

- Integrate predictive maintenance into asset strategies, supplementing calendar-based servicing with real-time intervention triggers.

For IPPs, this approach protects power purchase revenues and ensures NRS 048 compliance. For mines, it prevents production downtime and protects ageing infrastructure. For commercial operators, it helps avoid equipment failures and maintain customer confidence.

A strategic shift in asset management

Transformers can no longer be treated as “fit-and-forget” assets. In an environment shaped by renewables integration, theft, blackouts and fluctuating demand, continuous monitoring and proactive intervention are becoming essential.

Technologies such as VECTO 3, which combine high-resolution waveform analytics, fault logging and edge computing, are giving asset owners the visibility needed to maximise return on investment and extend transformer operating life.

If your transformers could speak, what would they warn you about?

Read the full engineering guide to monitoring and future-proofing transformers across IPP, mining and commercial sites: vectosystem.com/transformer-strategy/

Prefer listening to a podcast? Visit vectosystem.com/transformer-strategy-podcast/