Incorrect application of international standards governing horizontal post insulators could be introducing unintended mechanical risks into overhead power line designs, particularly as utilities and developers push for more compact pole-top configurations to accommodate growing electricity demand.

A technical paper, presented by Allan Muir of South Africa-based Mace Technologies during the CIGRE Southern Africa Regional Conference in Pretoria in October 2025, highlights persistent misunderstandings about the use of combined load formulae set out in IEC 61952, which governs composite line post insulators for overhead lines above 1 kV.

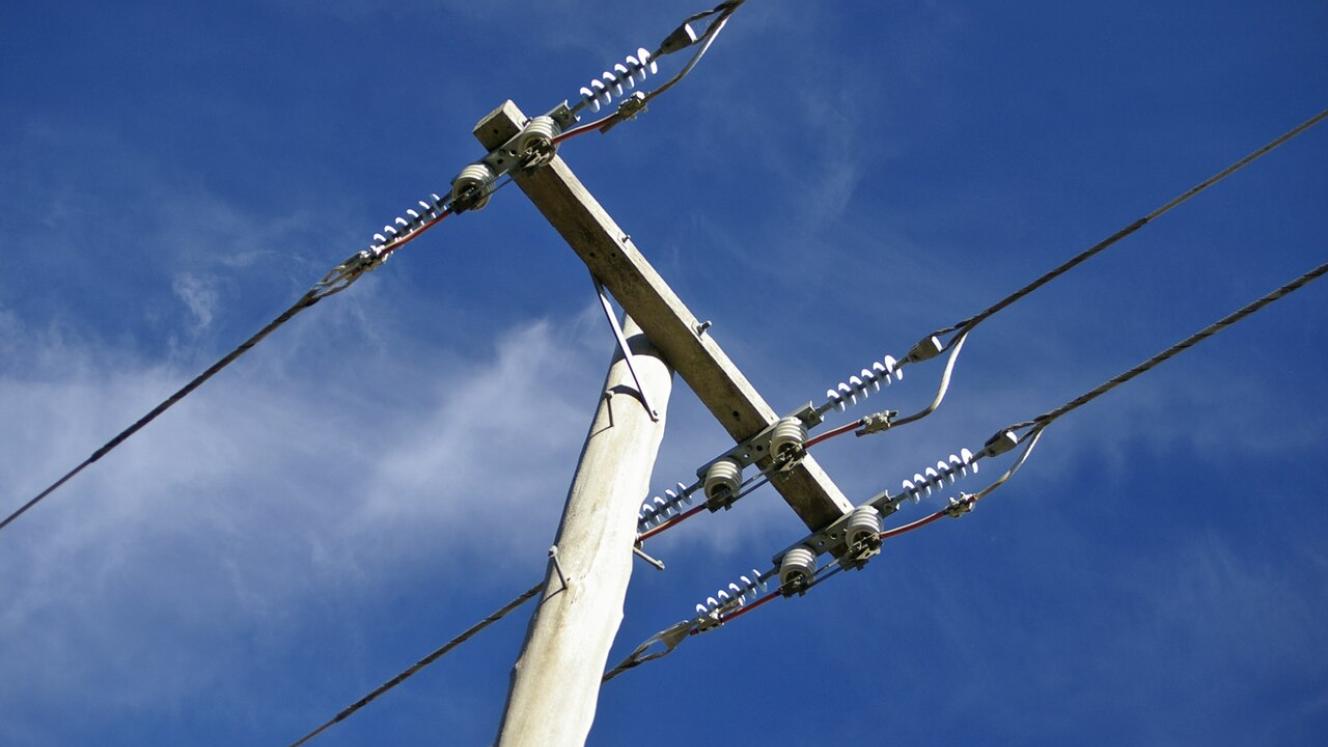

Horizontal post insulators, commonly used on wooden, concrete and steel monopoles between 11 kV and 132 kV, have become increasingly prevalent as space constraints, servitude limitations and the move towards monopole structures drive more compact line designs. However, Muir warns that, as these insulators are deployed at higher voltages with longer spans and heavier conductor bundles, they are being pushed closer to their mechanical limits.

According to Muir, a key concern is the way IEC 61952 combined mechanical load equations are being applied in practice. While the standard provides well-defined formulae for assessing the combined effects of vertical, transverse and longitudinal loads on horizontal post insulators, discrepancies have emerged in load capacity curves issued by different manufacturers. These discrepancies, Muir argues, point to widespread misapplication of the formulae – particularly where equations intended for ultimate load conditions are instead used to define working load limits.

This misinterpretation poses a specific risk in relation to compressive loading. While working stress limits may be reduced through safety factors, Muir notes that compressive buckling limits remain unchanged. As a result, designs that appear compliant under assumed “working load” conditions may still be operating dangerously close to buckling failure in the field.

The issue is compounded when incorrect assumptions are carried through into the design of braced post insulator assemblies, which are often introduced to strengthen horizontal posts that have reached their cantilever limits. Errors at this stage can propagate through design software, capacity tables and construction drawings, increasing systemic risk across entire line sections.

Beyond standards interpretation, Muir also draws attention to the growing importance of installation angle optimisation. Analysis shows that relatively small changes in installation angle can materially improve an insulator’s vertical load capacity across a wide range of operating conditions. However, real-world installation tolerances, particularly in anchor-cap end fittings, can reduce the achieved angle by several degrees compared to the design intent, potentially undermining these optimisations.

The findings have practical implications for overhead line designers, utilities and EPC contractors, especially as compact tower-top configurations are increasingly favoured for their material and cost efficiencies. While horizontal post insulators can reduce steel requirements, foundation sizes and wind-loading effects, Muir cautions that these benefits rely on rigorous mechanical modelling and correct standards application.

Muir concludes that IEC 61952 combined load equations should only be used to generate combined ultimate load curves, which are then factored appropriately to derive meaningful working load limits. Failure to follow this methodology risks exposing post insulators to compressive buckling under conditions that may be mistakenly regarded as safe, he warns.

Further work is planned to extend the analysis to braced post insulator theory, building on the framework established for horizontal post insulators.