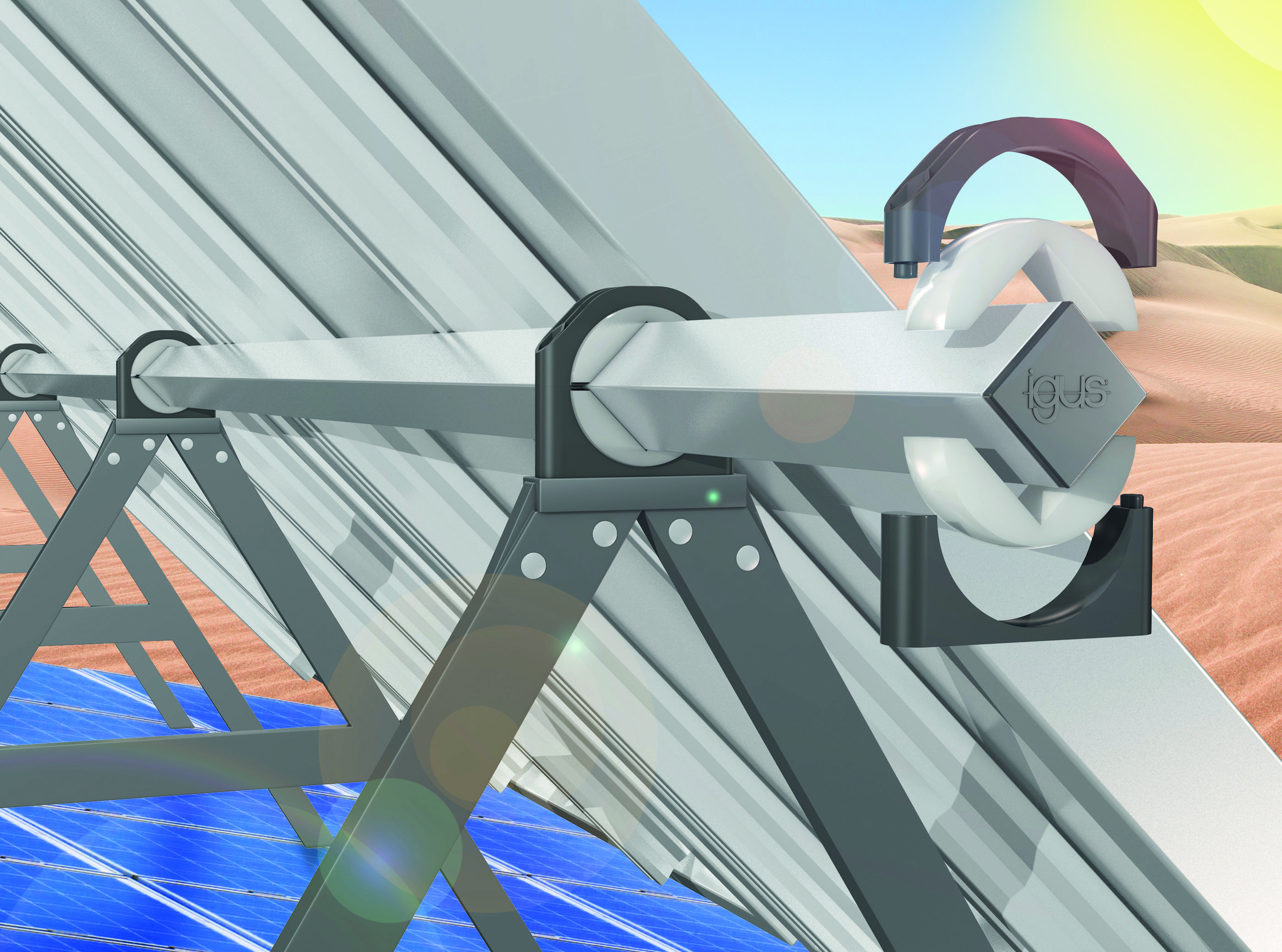

A critical point of failure on large-scale solar panels has been addressed with the introduction of polymer bearings that dramatically improve the lifespan of the part and nulifies the need for maintenance.

Solar panels need to track the sun for maximum efficiency and the bearings that facilitate the movement usually take a beating and require regular maintenance to operate for any length of time in the harsh, arid and dusty climates where solar farms are traditionally located. As a result, polymer bearing manufacturer, igus South Africa has worked with some of the country’s top design engineers to solve the problem and introduced its no-maintenance long life pillow block bearing.

Versatile solution

According to design engineer, Gerrit-Jan Cronselaar, of Super Armature Winding Africa, the designers and manufacturers of the SolTrac line of solar trackers, the pillow block design has eased the installation of its system as slight misalignment of the piles driven into the ground can be accommodated in the bearing itself rather than the pile/mounting hardware. This leads to faster and easier installation, saving effort and money in the process.

“The igus bearings have a long product warranty and longevity, are maintenance free and can handle dust and typical harsh conditions faced in African solar application areas. No other “traditional” bearing is available that can achieve similar performance and the design would have to be a lot more involved if bushes and an under swung design needs to be considered,“ says Gerrit.

Ian Hewat, managing director of igus South Africa, says bearings used in the alignment of the panels with the sun are typically the only moving parts, so need extra care when specifying these critical components.

Lubrication free

“Our bearings are a lubrication-free solution, whose durability has been tested in the laboratory and is guaranteed for 25 years. Tests in our own 3800 m2 test laboratory in Germany showed that the service life, wear resistance and load capacity were examined under real loads of the daily motion sequence, simulated in a time-lapse.

“The number of movements achieved under a load of 1,5 t corresponds to a service life of 72 years. This is why igus guarantees a runtime of 25 years, which corresponds to the standard service life of a solar module,“ says Ian.

Contact Ian Hewat, igus South Africa, Phone 011 312-1848, Fax 011 312-1594, ihewat@igus.de, www.igus.co.za